E faʻapefea ona faʻaleleia e le faʻaopoopoga silicone le faʻagasologa o le PS ma faʻalelei ai le luga?

E faʻapefea ona faʻaleleia e le silicone additive le faʻagasologa o le PS ma le lamolemole o le fogaeleele?

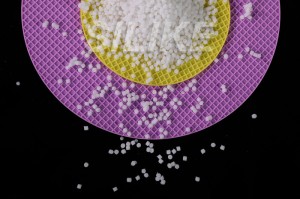

Fa'agasologa PS ma le luga lamolemole, Fa'aopoopoga Silikoni, Silikoni Masterbatch,

Fa'amatalaga

Silikoni Masterbatch(Siloxane Masterbatch) LYSI-410 o se fa'atulagaga pelletized ma le 50% ultra high molecular weight siloxane polymer ua fa'asalalauina i le High impact polystyrene (HIPS). E fa'aaogaina lautele o se fa'aopoopoga lelei i le fa'agasologa o le PS compatible resin system e fa'aleleia atili ai meatotino fa'agasologa ma suia ai le lelei o le fogāeleele.

Fa'atusatusa i mea fa'aopoopo masani e maualalo le mamafa o le molecular Silicone / Siloxane, e pei o le suāuu Silicone, vai silicone po'o isi ituaiga mea fa'aopoopo fa'agaioiga, SILIKESilikoni MasterbatchO le faasologa o LYSI e faʻamoemoe e maua ai ni faʻamanuiaga faʻaleleia atili, mo se faʻataʻitaʻiga,. E itiiti le seʻe o le faovilivili, faʻaleleia atili le tatalaina o le popole, faʻaitiitia le tafe o le palapala i totonu o le masini, maualalo le coefficient of friction, itiiti faʻafitauli o vali ma le lolomiina, ma se lautele atu o gafatia faʻatino.

Fa'avae Autu

| Vasega | LYSI-410 |

| Foliga vaaia | Pellet pa'epa'e |

| % o le aofa'i o le silikoni | 50 |

| Fa'avae resini | SUĀ'ULU |

| Fa'asinomaga o le liusuavai (230℃, 2.16KG) g/10min | 13.0 (tau masani) |

| Fua fa'atatau% (w/w) | 0.5~5 |

Fa'amanuiaga

(1) Fa'aleleia atili meatotino fa'agasologa e aofia ai le lelei o le tafe, fa'aitiitia o le tafe o le palapala, fa'aitiitia le malosi o le extruder, fa'aleleia atili le fa'atumuina ma le fa'asa'olotoina o le fa'a'ofuofu

(2) Fa'aleleia le tulaga lelei o le fogāeleele e pei o le se'e o le fogāeleele, fa'aitiitia le Coefficient of friction

(3) Tete'e sili atu i le olo ma le valu

(4) Vave le gaosiga, fa'aitiitia le fua fa'atatau o le fa'aletonu o oloa.

(5) Fa'aleleia le mautu pe a fa'atusatusa i le fesoasoani masani i le fa'agasologa po'o le fa'asusu

Talosaga

(1) Seevae TPR/TR

(2) Elastomers thermoplastic

(3) Palasitika fa'ainisinia

(4) Isi faiga e fetaui ma le PS

Fa'afefea ona fa'aaoga

E mafai ona fa'agasolo le SILIKE LYSI series silicone masterbatch i le auala lava e tasi e pei o le resin carrier lea na latou fa'avae ai. E mafai ona fa'aaogaina i le faiga masani o le fa'afefiloi o le melt e pei o le Single/Twin screw extruder, injection molding. E fautuaina se fa'afefiloi fa'aletino ma ni polymer pellets fou.

Fua fa'atatau

A fa'aopoopo i le polyethylene po'o se thermoplastic fa'apena i le 0.2 i le 1%, e fa'amoemoeina le fa'aleleia atili o le fa'agasologa ma le tafe o le resin, e aofia ai le fa'atumuina lelei o le mold, itiiti ifo le extruder torque, internal lubricants, mold release ma le vave throughput; I se tulaga fa'aopoopo maualuga, 2~5%, e fa'amoemoeina le fa'aleleia atili o meatotino o luga, e aofia ai le lubricity, slip, maualalo le coefficient of friction ma le tele o le mar/scratch ma le tete'e atu i le abrasion.

Afifi

25Kg / taga, taga pepa galuega taulima

Teuina

Felauaiga e pei o ni vailaʻau e le matautia. Teu i se nofoaga malūlū ma e lelei le ea.

Ola e teu ai

E tumau pea uiga muamua mo le 24 masina mai le aso na gaosia ai, pe afai e teuina i le nofoaga e fautuaina.

O Chengdu Silike Technology Co., Ltd o se kamupani gaosi ma fa'atau atu mea e fai i le silicone, o lē ua tuuto atu i le R&D o le tu'ufa'atasiga o le Silicone ma le thermoplastics mo le 20 tausaga.+ years, products including but not limited to Silicone masterbatch , Silicone powder, Anti-scratch masterbatch, Super-slip Masterbatch, Anti-abrasion masterbatch, Anti-Squeaking masterbatch, Silicone wax and Silicone-Thermoplastic Vulcanizate(Si-TPV), for more details and test data, please feel free to contact Ms.Amy Wang Email: amy.wang@silike.cnPS sheet is a material made of general-purpose polystyrene resin, some of our PS material clients told us when their downstream client produces 40 thread thickness polystyrene sheets if 50 sheets are cut at the same time, the surface of the products will have fuzz flash issues. when added SILIKE silicone additive to polystyrene at 2.0%, improved processing and flow of the resin are expected, in addition, the final PS sheet has good toughness, smooth surface that can cut PS sheet in a wanton shape, get good kerf and smooth edge.

FA'AOGA SILICONE E LEAI SE TOTOGI MA FA'ATA'ITA'IGA Si-TPV E SILI ATU I LE 100 VAEGA

Ituaiga faʻataʻitaʻiga

$0

- 50+

vasega Silicone Masterbatch

- 10+

vasega Silicone Powder

- 10+

vasega Masterbatch e tete'e i valu

- 10+

vasega Anti-abrasion Masterbatch

- 10+

vasega Si-TPV

- 8+

vasega Silicone Wax

-

Telefoni

-

Imeli

-

Whatsapp

Whatsapp

-

Pito i luga

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur