Auala e fa'aleleia atili ai le tapuvae seevae

Auala e faʻaleleia atili ai le puipuiga o le tapuvae seevae mai le oloina,

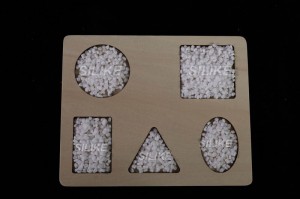

Masterbatch e tete'e atu i le oloina, Masterbatch e tete'e ai i le abrasion mo le tapuvae seevae, Mea e Tete'e ai i le Ofu, TPR, TR,

Fa'amatalaga

O le Anti-abrasion Masterbatch (Agena e tete'e i le ofuina) NM-6 o se fa'atulagaga pelletized ma le 50% o mea aoga e fa'asalalauina i totonu o le Thermoplastic polyurethanes (TPU). Ua fa'apitoa ona atia'e mo le fa'aputuga o tapuvae o seevae TPU, e fesoasoani e fa'aleleia atili ai le tete'e atu i le olo ma fa'aitiitia ai le taua o le olo i totonu o le thermoplastics.

Pe a fa'atusatusa i mea fa'aopoopo masani e maualalo le mamafa o le Silicone / Siloxane, e pei o le suāuu Silicone, vai silicone po'o isi ituaiga mea fa'aopoopo e abrasion ai, o le SILIKE Anti-abrasion Masterbatch NM-6 e fa'amoemoe e maua ai se uiga sili atu ona tete'e atu i le abrasion e aunoa ma se a'afiaga i le ma'a'a ma le lanu.

Fa'avae Autu

| Vasega | NM-6 |

| Foliga vaaia | Pellet pa'epa'e |

| % o mea aoga | 50 |

| Resin feavea'i | TPU |

| Fa'asinomaga o le liusuavai (190 ℃, 2.16KG) | 25.0 (tau masani) |

| Fua fa'atatau % (w/w) | 0.5~5% |

Fa'amanuiaga

(1) Fa'aleleia atili le tete'e atu i le oloina fa'atasi ai ma le fa'aitiitia o le taua o le oloina

(2) Fa'ailoa atu le fa'atinoga o le fa'agasologa ma le foliga vaaia o mea mulimuli

(3) Fa'alelei i le siosiomaga

(4) Leai se aafiaga i le ma'a'a ma le lanu

(5) Aoga mo suega o le oloina o le DIN, ASTM, NBS, AKRON, SATRA, GB

Talosaga

(1) Seevae TPU

(2) Isi palasitika e fetaui ma le TPU

Fa'afefea ona fa'aaoga

E mafai ona fa'agasolo le SILIKE Anti-abrasion masterbatch i le auala lava e tasi e pei o le resin carrier lea na latou fa'avae ai. E mafai ona fa'aaogaina i le faiga masani o le fa'afefiloi o le melt e pei o le Single/Twin screw extruder, injection molding. E fautuaina se fa'afefiloi fa'aletino ma ni pellets polymer fou.

Fua fa'atatau

A fa'aopoopo i le TPU po'o se thermoplastic fa'apena i le 0.2 i le 1%, e fa'amoemoeina le fa'aleleia atili o le fa'agasologa ma le tafe o le resin, e aofia ai le fa'atumuina lelei o le mold, itiiti ifo le extruder torque, internal lubricants, mold release ma le vave throughput; I se tulaga fa'aopoopo maualuga, 1~2%, e fa'amoemoeina le fa'aleleia atili o meatotino o luga, e aofia ai le lubricity, slip, maualalo le coefficient of friction ma le tele o le mar/scratch ma le abrasion resistance.

Afifi

25Kg / taga, taga pepa galuega taulima

Teuina

Felauaiga e pei o ni vailaʻau e le matautia. Teu i se nofoaga malūlū ma e lelei le ea.

Ola e teu ai

E tumau pea uiga muamua mo le 24 masina mai le aso na gaosia ai, pe afai e teuina i le nofoaga e fautuaina.

O Chengdu Silike Technology Co., Ltd o se kamupani gaosi ma fa'atau atu mea e fai i le silicone, o lē ua tuuto atu i le R&D o le tu'ufa'atasiga o le Silicone ma le thermoplastics mo le 20 tausaga.+ years, products including but not limited to Silicone masterbatch , Silicone powder, Anti-scratch masterbatch, Super-slip Masterbatch, Anti-abrasion masterbatch, Anti-Squeaking masterbatch, Silicone wax and Silicone-Thermoplastic Vulcanizate(Si-TPV), for more details and test data, please feel free to contact Ms.Amy Wang Email: amy.wang@silike.cnThere are a variety of anti-abrasion masterbatches available for shoe sole applications. These masterbatches are typically made from a combination of polymers, fillers, and additives that provide increased abrasion resistance and durability. Common polymers used in these masterbatches include SBS, EVA, TR, TPR, rubber, and polyurethane. Fillers such as carbon black, silica, and talc are also used to improve abrasion resistance.

FA'AOGA SILICONE E LEAI SE TOTOGI MA FA'ATA'ITA'IGA Si-TPV E SILI ATU I LE 100 VAEGA

Ituaiga faʻataʻitaʻiga

$0

- 50+

vasega Silicone Masterbatch

- 10+

vasega Silicone Powder

- 10+

vasega Masterbatch e tete'e i valu

- 10+

vasega Anti-abrasion Masterbatch

- 10+

vasega Si-TPV

- 8+

vasega Silicone Wax

-

Telefoni

-

Imeli

-

Whatsapp

Whatsapp

-

Pito i luga

- English

- Chinese

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur